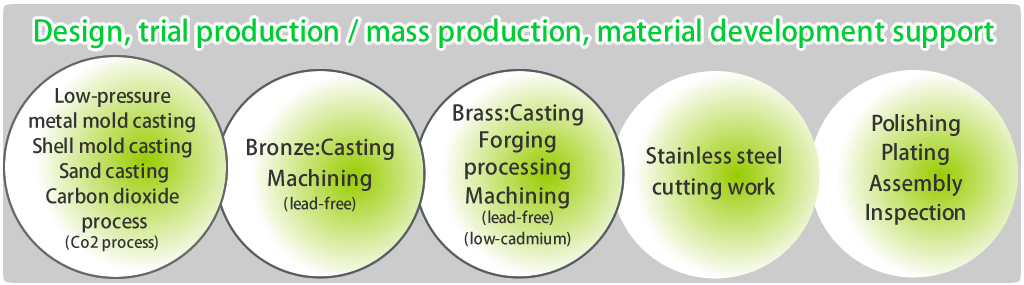

We comprehensively support our clients’ improved efficiency and response to the environment

With our capable personnel and a variety of company-owned production equipment, we work in design, from trial to mass production in a consistent manner tosupport your improved efficiency.We will provide great benefit by proposing and performing efficient manufacturing suitable for contracted products.

As for copper alloy, we can provide you with assistance from the development of alloy materials to comprehensively support manufacturing.

We will:

- Select and develop efficient materials tailored to products and use;

- Select and propose an efficient production method suitable for the use and shape of products;

- Reduce energy consumption in the production process;

- Reduce waste generated in the production process;

- Respond to environmental concerns by reviewing production methods; and,

- Advance delivery dates and reduce costs.

Casting Department

Casting Department »- Contracting for manufacturing copper alloy castings

Division Material name ASTM(USA) Lead Free RoHS JIS Yellow Brass C85700

{Leaded yellow brass}OK

(With condition)CAC203 Bronze C84400

{Leaded semi-red brass}NOT CAC401(BC1) C83600

{Leaded red brass}NOT CAC406(BC6) C92200

{Leaded tin bronze}OK CAC407(BC7) Silzin bronze Ecobrass C87850

{Silicon brass}Lead

FreeOK CAC804 Ecobismuth (CDA C89841) Lead

FreeOK – ASTM C87800

Silicon BronzeC87800

{Silicon Bronze}Lead

FreeOK – Ecobronze – Lead

FreeOK – Bismuth bronze – Lead

FreeOK CAC901 C89844

{Bi semi-red brass}Lead

FreeOK CAC902 Lead

FreeOK CAC903 Bismuth-selenium bronze keepalloy C89530 (B30 B584)

{Bi-Selenium brass}Lead

FreeOK CAC911 C89535

{Bi-Selenium brass}Lead

FreeOK CAC912 Special material Dezincification-Resistant Brass – OK

(With condition– Copper-Zinc-Tin-Bisumuth KITZ Corporation

SAN-ETSU METALS– Lead

FreeOK – keepalloy C49300

{Copper-Zinc-Tin-Bisumuth}Lead

FreeOK – - Design and development of copper alloy castings and trial production of copper alloy castings

- Support for development of copper alloy materials

- We will ask you to utilize our equipment and knowlege after concluding necessary contracts in accordance with the development details.

Machining Department

Machining Department »- Contracting for cutting and other works for various types of metal

Materials available for machining:

- Brass and Bronze

- Casting materials

- Forging materials

- Bar materials

- Stainless Steel

- Bar materials

- Other Alloy

- Brass and Bronze

Jigs,Tools,and Trial Production Department

- Design and manufacturing of jigs for sales

- Contracting for trial production

- Design and manufacturing of in-house jigs and tools

Surface Treatment Department (including buffing)

- Contracting for surface treatment of metals (including buffing and plating)

- Materials available for buffing:

- Brass and Bronze Alloy

- Stainless Steel

- Other Alloy

- Other types of surface treatment available (subcontract factories):

- Plate processing

- Ion plating

- NPB processing

- Blast processing

- Materials available for buffing:

Assembly and Inspection Department (including brazing and soldering)

- Contracting for assembly and inspection of components

- Faucet bracket assembly

- Procurement and assembly of other items

- Brazing and soldering metallic parts

- Final inspection of product performances

Supply of parts and product

Product examples »- Import and sale of die-casting products.

- Aluminum Die Casting products

- Zinc Die Casting products

- Import and sale of Lost Wax products.

- Stainless Steel Lost Wax products