We are equipped with three main types of machining equipment to achieve domestic production in a consistent manner from casting and processing to finishing.

We accept both small lot orders and those for tens of thousands of pieces. We also accept outsourced processing with the materials supplied.

- 1.NC lathe

- 2.Machining center

- 3.Hexaxial automatic cutting machine for casting processing

- Other processing equipment

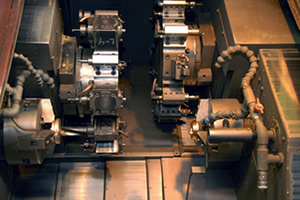

1.NC Lathe Equipment

The 24-h operating equipment consists mainly of the combined CNC lathe with 2 spindles and 2 saddles.

We have a processed/finished product aligner installed for preventing scratches and dents. This developed equipment minimizes distortions and scratches generated in the production process, allowing us to supply processed products of higher quality.

- Processible materials:

- Stainless Steel.

- Brass and Bronze.,Lead free Brass and Bronze.

- Processible size:

- φ5 mm to φ250 mm

- Deformed forgings or castings can also be processed.

- Processible lot size:

- Several units to tens of thousands of units/month

- We also accept test production.

Equipment Types

- Combined lathe with 2 spindles and 2 saddles (bar type): 4 units (Nakamura-tome)

- Combined lathe with 2 spindles and 2 saddles (chucker type): 2 units (Nakamura-tome)

- Combined lathe with tailstock (chucker type): 1 unit (MAZAK)

- Combined lathe with tailstock (chucker type) with robots: 1 unit

- Combined lathe with sub-spindle (bar type): 2 units (Nakamura-tome)

- Combined lathe with spindle traverse (bar type): 2 units (Tsugami, Star Micronics)

- Vertical lathe: 1 unit

- Discharged workpiece aligner: 6 units

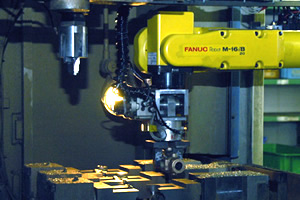

2.Machining Center Equipment

The equipment consists mainly of the #40 vertical machining center.

A robot is equipped with some machining centers.

The equipment achieves the 24-h operating production system.

We intend to add more robots to further improve productivity.

The rotating dividing index chuck is installed.

A single chucking allows processing from various angles.

- Workpiece shape:

- We are excellent at processing deformed forgings or castings.

- Of course, we process logs or blocks.

- Processible materials:

- Stainless Steel.

- Brass and Bronze,Lead free Brass and Bronze

- Processible lot size:

- Several units to tens of thousands of units/month

- We are also pleased to accept casting or forging materials for processing only regardless of the lot size.

Equipment Types

- #40 vertical machining center with robot: 2 units

- #40 vertical machining center: 4 units

- #30 tapping center with loader: 1 unit

- Index chuck

3.Hexaxial automatic cutting machine

This cutting machine has two spindles for three different directions.

It is useful for boring using a formed tool for deformed castings or forgings, and for threading that uses a tap and die. The machine equipped with loaders that supply and discharge workpieces allows semi-unattended operation.

The machine is suitable for processing casting parts requiring high-quality processing despite small lot sizes.

Machining capability

- Threading by tap

- e.g., Bronze casting: A taper pipe thread as large as Rc2 (2-inch female taper thread) can be processed.

- Threading by die

- e.g., Bronze casting: A taper pipe thread as large as R1 (1-inch male taper thread) can be processed.

- Processible materials:

- Brass and Bronze.,Lead free Brass and Bronze.

- Processible lot size:

- Several units to tens of thousands of units/month

- We are also pleased to accept casting or forging materials for processing only regardless of the lot size.

Units Owned

- Hexaxial automatic cutting machine: 10 units

- Quadraxial automatic cutting machine: 1 unit

- Biaxial drill mirror: 2 units

Other Processing Equipment

- NC milling cutter: 1 unit (for experimental production and manufacturing of jigs and tools)

- General-purpose milling cutter: 2 units (for experimental production and manufacturing of jigs and tools)

- General-purpose lathe: 2 units (for experimental production and manufacturing of jigs and tools)

- Radial drilling machine: 1 unit (for experimental production and manufacturing of jigs and tools)

- Polygon machine: 1 unit

- Drilling machine: 4 units

- Mechanical Press Machine (for pressing and punching out metal to shape): 1 unit (press such as serration)

- Bandsaw cutting machine: 2 units

- Universal tool grinder

- Tool pre-setter

- Drill grinder