T1 Test to check molten metal flow and trial production

Metal mold temperature approximately 100°C

Temperature during pouring about 1015°C

Molten metal flow is good

Molten metal is filled all the way up to up-hill part for degassing.

When the product was made with a plan with fast molten metal flow supplied to product parts, overall run was sufficient.

Metal mold plan for permanent mold casting has a marked influence on molten metal flow.

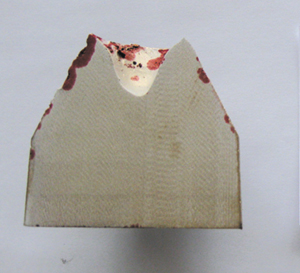

A defect was found in trial production caused by shrinkage in the part sandwiched by the core, which is the part that solidifies last.

We believe the defect can be resolved by using a different gate thickness and position.

The varying components due to Zn depletion in molten metal appeared to cause changes in the flow of molten metal.

T2 Teeter mold test

Result: Good It can be used for permanent mold casting

Internal shrinkage showed a smooth surface.

The deepest part of shrinkage did not contain any rough textured surface stained red on color check.(It is good)

A plan that considers the possibility of relatively large external overall shrinkage and relatively large and shallow internal shrinkage is required.

Metal mold casting conditions may not be suitable.

A temperature range must be used that is suitable for permanent mold casting.

T3 Confirmation of mechanical properties

Tensile strength: 357 N/mm2 Degree of elongation: 30%

Standards of common brass material and bronze were met sufficiently.

T4 Analysis and confirmation of molten metal components

| Cu | Sn | Pb | Zn | Fe | Bi | Se | Others | Cd | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 1. | Standard value | 57.5-60.5 | 1.0Max | 0.01Max | REM | 0.4Max | – | – | 0.15-0.55 | |

| 2. | Purchased materials | 58.8 | 0.2 | 0 | 40.78 | 0.01 | – | – | 0.21 | 6ppm |

| 3. | Before melting | 59 | 0.2 | 0.003 | 38.8 | 0.005 | 2.17 | 0.033 | 0.17 | 6ppm |

| 4. | At the time of test production | 59.3 | 0.29 | 0.004 | 37.52 | 0.007 | 1.96 | 0.033 | 0.2 | 6ppm |

Attention is required as Zn tends to be depleted and the value of Cu tends to increase.

T5 Confirming processability

It appeared to be viscous.

Chips are small but larger than those of common brass.

Processability is good.

T6 Evaluation of pressure resistance of trial production

Result

In the true trial production, the degree of leakage was lower, but we were unable to improve leakage from the part sandwiched by the core.Metal mold plan and casting condition have large effects on pressure resistance. We will continue to examine its properties.

Preliminary trial production

Leakage was observed in all products in preliminary trial production.Leakage was observed at the part sandwiched by core sand that solidifies last.There was no leakage at the part in direct contact with the metal mold.

True trial production

In the true trial production where plan and product thickness were changed, the degree of leakage was improved but the plan is not perfect.

Results and evaluation

If the components of molten metal are sufficiently managed, metal mold castability by permanent mold casting is good.

This material was not developed as a permanent mold casting material.

It can be used for sealed type low-pressure permanent mold casting.

Utilization in low-pressure permanent mold casting may be easier than in gravity metal mold casting method.

However, optimal balance of molten metal components and permanent mold casting conditions, such as pouring temperature and metal mold temperature, must be investigated.

Importance of the permanent mold casting plan is high, and it is necessary to change the characteristics of the plan from that used for common lead-containing brass