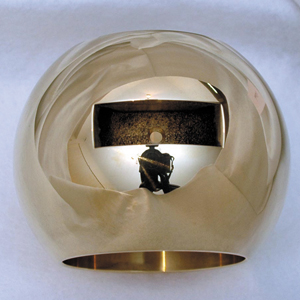

T1 Test to check molten metal flow and trial production

Metal mold temperature approximately 95°C

Temperature during pouring about 1010°C

Evaluation was not performed because the material is commonly used.

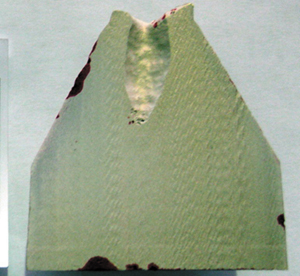

T2 Teeter mold test

Result: good It can be used for permanent mold casting

The surface of the internal shrinkage had slight unevenness but was relatively smooth.

In color check at the deepest part of the shrinkage, a small amount of rough texture was observed. (It is within the range with no problem. )

Usually, this result is considered good, and permanent mold casting is possible without any problems.

T3 Confirmation of mechanical properties

Tensile strength: 351 N/mm2 Degree of elongation: 28%

Standards of common brass material and bronze were met sufficiently.

T4 Analysis and confirmation of molten metal components

| Cu | Sn | Pb | Zn | Al | Cd | ||

|---|---|---|---|---|---|---|---|

| 1. | Standard value | 58.0-64.0 | 0.3Max | 1.5-2.5 | REM | 0.5-0.7 | |

| 2. | Purchased materials | 59.55 | 0.05 | 1.87 | 37.91 | 0.601 | 9ppm |

| 3. | Before melting | 59.2 | 0.04 | 1.64 | 38.25 | 0.73 | 10ppm |

| 4. | At the time of test production | 59.5 | 0.1 | 1.63 | 37.87 | 0.65 | 10ppm |

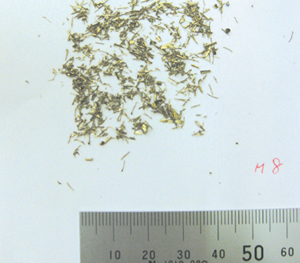

T5 Confirming processability

Processability is good.

T6 Evaluation of pressure resistance of trial production

Evaluation was not performed because the material is commonly used.

Results and evaluation

Evaluation was not performed because the material is commonly used.